.jpg) Shells

Shells

The term here depends on the literature source. RCA called them envelopes, Sylvania called them shells, others used either term as they saw fit. Regardless, a shell (or envelope) is the tube enclosure. On tubes prior to the 1950s, it would usually be the part above the base. On tubes from the 1950s onward, it would usually be the entire enclosure. Shells were made out of metal or glass.

Prior to about 1935, all tubes used glass shells, probably because they evolved from electric light bulbs. Beginning in 1935, coinciding with the octal era, General Electric and RCA began selling tubes with metal shells (though I also have a CeCo 55 tube from 1934/35).

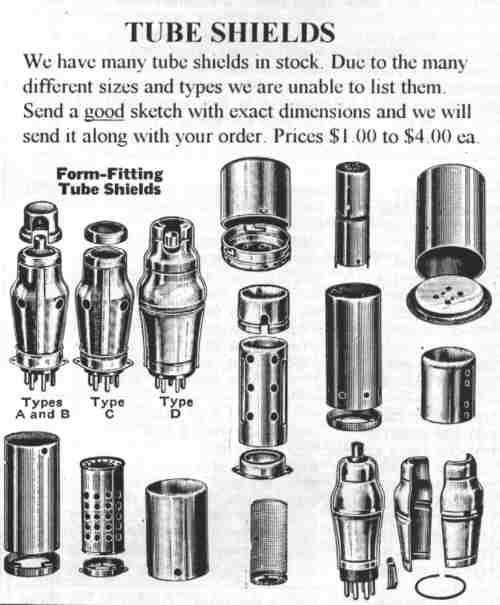

There were a few of benefits to using metal shells. First was that it provided built-in shielding for sensitive amplifiers. On octal tubes, metal shells was connected to pin 1 which could then be grounded. Glass tubes still required an exterior metal enclosure to do the same thing. The second was that metal shells had slightly smaller internal capacitance ratings than their glass versions. How useful this was depended largely on the engineer who designed the curcuit around it, as well as the quality of the manufacturing process. And of course, metal tubes didn't break when they were dropped.

One of the obvious drawbacks was that one couldn't see whether the filament lit; either a continuity test had to be done or the tube had to be given a chance to warm up to determine whether the filament was broken or not.

Metal tubes started a controversy in the mid-30s when they were introduced. GE, RCA and other metal-tube-makers hailed them as an advantage over glass. RCA's rivals, like Sylvania and Philco, dismissed them as a gimmick. Considering that the radio market during the depression was filled with a long list of innovations, new features, design points, fast-changing fashion trends and sales gimmicks of all sorts, they were at least partly right. The metal era lasted as long as octals were being made, but the next generation of tubes would be all glass.

Metal tubes started a controversy in the mid-30s when they were introduced. GE, RCA and other metal-tube-makers hailed them as an advantage over glass. RCA's rivals, like Sylvania and Philco, dismissed them as a gimmick. Considering that the radio market during the depression was filled with a long list of innovations, new features, design points, fast-changing fashion trends and sales gimmicks of all sorts, they were at least partly right. The metal era lasted as long as octals were being made, but the next generation of tubes would be all glass.

Personally, I like metal shells. I prefer them any time I have the choice. My favorite thing about them is that they've got the best paint. Many glass tubes have the paint rubbed off, sometimes entirely, sometimes just nearly so. Metal tubes are typically black with white paint, and all but those in the very worst condition are still fairly easy to read. Glass tubes can often be a struggle to read.

Tube shapes tended to fall into only a few categories. Tubular types went straight up—the width at the top was the same as the base. These were usually "T" types. "S" types were straight-sided but wider near the top than the base, and resembled a slim hot-air balloon. "ST" types were a hybrid: the silhouette looked like an "S" with a "T" type superimposed.

S types were most common in the 1920s, and the shape was often called a "globe" tube. 20s-era tubes that continued on into the 30s usually changed to the ST shape, so it's possible to find the same tube designation (e.g. an 01A) with different tube envelope shapes.

Bases and Pin-outs

The problem with tubes is how to connect them to the rest of the circuit. Early on, manufacturers decided to connect the internal electrodes to pins that extended out from the base of the tube. The base was made out of metal (usually copper colored) or bakelite (black). In some cases the tube would be pushed into a socket and given a quarter turn, bayonet-style, to lock in place, but eventually the favorite way was to simply to push the tube straight down into the socket, and let the socket hold the pins strongly enough to keep the tube from "walking" out. Almost all tube types from World War I onward use some variation of this scheme.

Pre-Octals

The earliest tubes were hand-made by glass-blowers. But beginning in the 1920s, radio boomed as ordinary people began tuning in to voice and music broadcasts. The best radios required tubes as detectors and amplifiers, so people began mass-manufacturing tubes. The development of radio and tube technologies fed each other, and sales of both built upward.

In the 1920s when tubes were starting to be mass-manufactured, they were just "tubes." There's no term for this first era of manufactured tubes, so I call it pre-octal. It's as good as anything I've seen and better than most.

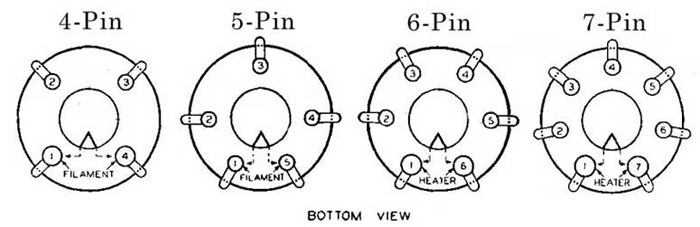

Pre-octal tubes are standardized on a few common sockets. Each socket differed by the number of pins on the tube. The most common socket had four pins, but there are five, six and seven pin versions.

Pins are counted from the viewpoint of the bottom of the tube (you're looking at the pins directly). Numbering begins at the 6 o'clock position and goes clockwise, so Pin 1 is the first pin on the bottom left, and the last pin in the bottom right.

One of the problems with early tubes is that if the pins were symmetrically spaced, it was possible to plug the tube in incorrectly. Pre-octals got around this a couple of different ways. The first is that the filament (heater) pins were slightly larger than the others, so they could only fit into the proper holes in the socket. Filament pins were also usually spaced a little differently, which again made the tube fit the socket only one way. Many bases also had a little arrow that pointed to the space between the first and last pins (e.g. between Pins 1 and 4, or 1 and 6), but it may not always be there.

Filaments on pre-octals are nearly always the first and last pins on the tube.

Some pre-octals had grid-caps (colloquially called tin hats), which are metal caps located on the top or sides of the shell, and provided a separate electrode connection away from the base. This was usually the control grid, as this put the signal input wiring away from the rest and reduced interference. Basing diagrams that included grid caps would show the grid-cap outside connection outside of the base.

Octals

The octal base debuted in the mid 1930s and was a major part of the tube era. Octals were a way of addressing a number of problems.

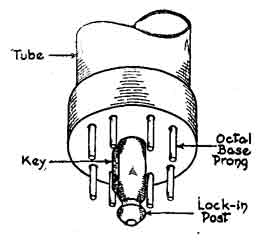

First of all, they did away with the various sizes and pin configurations and went with a single standard socket and base. There are eight pins, symmetrically placed and identically sized. There's a much larger non-conductive pin in the center with a ridge on it that acts as a key; the socket has a hole with a key-way, so that the tube can only fit one way. The center pin is also longer than the conductive pins. This makes octal tubes very easy to seat—you set the tube on top of the socket and turn it until the center pin catches the key and the tube drops a bit—that means everything's lined up—then push. Works like a charm.

Octal tubes had smaller interelectrode capacitance, so they generally worked better for RF and IF amplification. Short wave amplifier tubes were the first to be replaced by octals; power output tubes hung on longer. Power rectifier tubes were the last to go.

Octals were the first (with a few possible exceptions) to come with metal shells as well as glass.

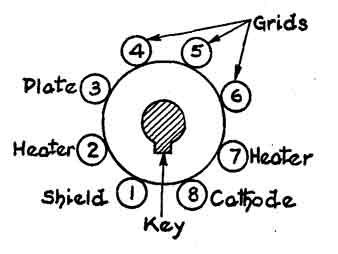

Since octal basing has only socket, the rules are simple. Again, the viewpoint is from the bottom of the tube. With the key pointing directly down (6 o'clock), count clockwise.

Since octal basing has only socket, the rules are simple. Again, the viewpoint is from the bottom of the tube. With the key pointing directly down (6 o'clock), count clockwise.

Pin #1 on an octal tube is always the shield (on metal tubes) or no connection on glass tubes. There are no exceptions. Radios with glass octal tubes sometimes use the #1 pin as a convenient binding post.

Most octals used pins 2 and 7 as the heater pins (2 and 8 if there was no separate cathode), but a number used 7 and 8 as the filament. Likewise, octals typically put the plate on pin 3, the cathode in pin 8, and grids or other elements on 4, 5 and 6, but this isn't a hard rule, just a convention.

Many octals don't need all eight pins. Some tubes had all eight pins and no internal connections; some tubes eliminated the excess pins and simply left blank spaces. There was talk of coming out with octal sockets that omitted connections for tubes that lacked the corresponding pins, but that never took hold: nobody wanted to stock several versions of nearly identical sockets; the inventory headaches and expense outweighed the tiny cost savings of the sockets themselves.

Octals are my personal favorite tubes. They're not the best tubes for every application, but I think in terms of practical use and design, they're the best. They're a moderate size—easy to grab, hold and manipulate. They have paint that rarely rubs completely off. The metal ones have their own shielding and the paint is easy to read. The pins usually don't get bent and need straightening. And I think they'e just generally well behaved.

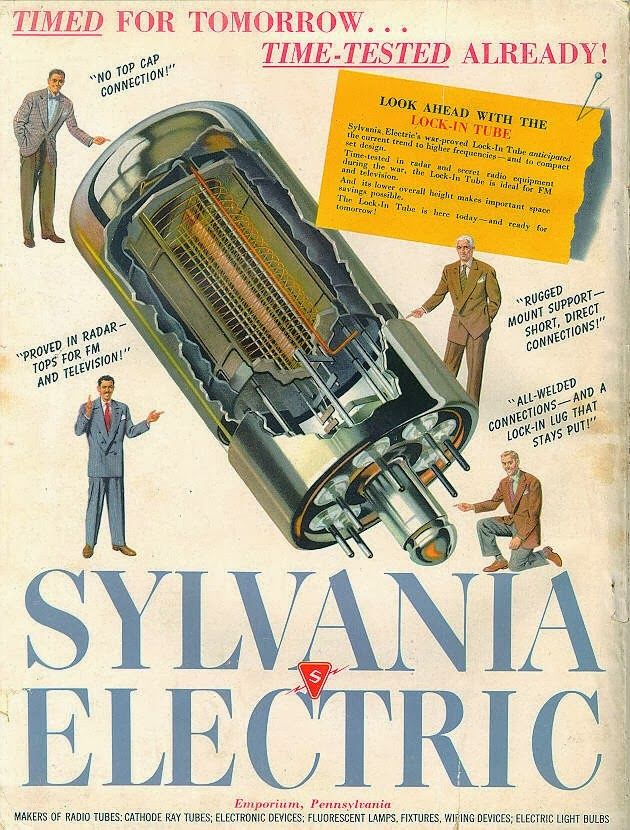

Loktals (aka Loctals, aka Lock-ins)

Loktals (often also spelled Loctal) are a variant of octals with a groove in the bottom of the center pin. As part of the socket, a spring-loaded catch would fit into the groove and hold the socket in place, hopefully preventing the tube from walking its way out of socket.

Loktals (often also spelled Loctal) are a variant of octals with a groove in the bottom of the center pin. As part of the socket, a spring-loaded catch would fit into the groove and hold the socket in place, hopefully preventing the tube from walking its way out of socket.

They were developed for, and mainly found in, mobile applications where the vibration or motion was severe enough that locking the tubes in place was a serious concern: automobiles, aircraft and marine radios tended to have them; so did portable radios like the early Zenith Trans-Oceanics. Loktals are also found in many regular radio sets where the manufacturer preferred Sylvania tubes over GE/RCA types; I have a couple of Philco table radios with Loktal tubes.

Loktals are infamous for doing the job too well—there are complaints that the locks freeze and the tubes are difficult to extract without pulling the chassis and attacking them from underneath. I've never personally had this happen, but I only have a few sets with these tubes. According to Sylvania, who developed the Loktal type, "Removal of these tubes from the sockets is difficult when done in a direct upward pull. With a slight off side pressure, the socket lock releases and removal is very easy." (Sylvania News, Vol. 8, #1, Jan-Feb 1939)

According to Wikipedia (and I've seen it repeated a couple of other places), Loktal with a k was Sylvania's tradename for the tubes, and Loktal with a c is the generic version. This may be the case but I am doubtful. The first mention I've seen of this type of tube is from Sylvania News, Volume 7, #9, May-June 1938, regarding the introduction of their Type 1231 tube. There is no mention of the locking feature at all. The next mention comes from a later issue of Sylvania News (Vol. 8, #1, Jan-Feb 1939), in which they coin the term Loktal. In the next issue, they use the term Loctal.

In all the later technical literature and print advertising that I've seen, Sylvania used the term lock-in tubes exclusively. I have no idea what went on in Sylvania's marketing department.

According to Wikipedia (and I've seen it repeated a couple of other places), Loktal with a k was Sylvania's tradename for the tubes, and Loktal with a c is the generic version. This may be the case but I am doubtful. The first mention I've seen of this type of tube is from Sylvania News, Volume 7, #9, May-June 1938, regarding the introduction of their Type 1231 tube. There is no mention of the locking feature at all. The next mention comes from a later issue of Sylvania News (Vol. 8, #1, Jan-Feb 1939), in which they coin the term Loktal. In the next issue, they use the term Loctal.

In all the later technical literature and print advertising that I've seen, Sylvania used the term lock-in tubes exclusively. I have no idea what went on in Sylvania's marketing department.

Loktals are very similar to octals: they're from about the same time period (late 30s), they had a universal 8-pin, non-conductive center post design. They were similarly sized. I don't know the real history of the development, but my guess is that GE/RCA and Sylvania were probably working on the same idea and then split apart mid-way in the process; the GE/RCA side went the octal route, and Sylvania went the Loktal route.

There are a number of differences. Loktals have smaller pins than octals, which reduces parasitic capacitance a little bit. Their bases are metal rather than bakelite, which harkens back to the 1920s and balloon tubes. There's the locking goove—a feature I never understood why octals didn't use (if they didn't need to be locked, why not just use a socket that omitted the locking mechanism?) And a big one: Loktals all had glass shells. Sylvania claimed that the metal base was shielding enough; if you wanted more, you needed to add it externally (and I've yet to see a loktal with an add-on shield in a commercial radio).

Unlike octals, where pin #1 was the shell on metal tubes and no-connection on glass, Loktals were able to use Pin 1 all the time for an electrical connection. So Loktal pin-outs were similar to early octals. Loktal heaters were typically pins 1 and 8, the plate was 2, the cathode was 7, and grids (or anything else) used pins 3 through 6.

Most Loktals can be identified simply by their nomenclature. Even though six-volt Loktals and octals both pulled the same 6.3-volts, and twelve-volt versions pulled 12.6-volts, octals start with 6 and 12 using the RMA/RETMA numbering system, while Loktals start with 7 and 14. So a 7A7 is really a 6.3-volt Loktal tube, and a 14X7 is a 12.3-volt Loktal tube.

In the Sylvania manuals, they do rate 7-series Loktals at 7-volts and 14-series Loktals at 14-volts, but list "typical operation values" as 6.3-volts and 12.6-volts respectively. According to Sylvania News, they could operate at 7 volts on a 130Hz AC system, or on 7-volts DC, which was the automobile standard at the time.

In fact, some Loktals are direct equivalents to common octal tubes. A 7A7 Loktal is electrically identical to an octal 6SK7, except for the socket and pin connections. Trans-Oceanic owners who have the expensive 1L6 miniature tube could consider subbing out a Loktal 1LA6, albiet with socket adapter and the proper wiring changes.

Miniatures

.jpg) Miniature tubes began to appear right after World War II and dominated the 50s. They're the last major change to be mass-produced and mass-utilized.

Miniature tubes began to appear right after World War II and dominated the 50s. They're the last major change to be mass-produced and mass-utilized.

Minis are easily recognized by their full-length glass shell—no bakelite or brass-clad-ceramic bases. The pins go straight through the outer shell. They come in various sizes but typically are a little shorter and a lot slimmer than octals or Loktals.

They typically come in two bases: 7-pin and 9-pin. The pins are symmetrical and evenly spaced in a circle pattern. 7-pin tubes are arranged as if they had 8 pins, but the 8th pin is missing; 9-pin tubes appear to be 10-pin tubes with the 10th missing. This gap acts as the key so that the tube can only fit the socket one way. There is no center, non-conductive locator pin with a key.

The lack of the center pin makes it a bit easier to bend the pins on miniatures, since it's easy to wiggle them out rather than pull them straight out. Because of this, pin-straightening tools (often a plain metal disc with 7 or 9 holes drilled in the proper pattern) were commonly used; you push the tube into the tool a couple times and the pins would straighten out. You could do the same thing with a socket, but the tool was heavy and could be easily held in your hand, whereas a socket is usually too small and light to hold securely. If you do much with miniature tubes, a pin straightening tool can be a handy thing to have around.

Besides the savings in size and weight, miniatures have smaller internal capacitance, which makes them work better at higher frequencies: miniatures show up when VHF and UHF equipment becomes commonly available (e.g. television). My Hallicrafters SX-42 boat anchor was one of the early receivers that went above the 30MHz; most of its tubes are octals, but it uses miniatures for the upper bands.

Besides the savings in size and weight, miniatures have smaller internal capacitance, which makes them work better at higher frequencies: miniatures show up when VHF and UHF equipment becomes commonly available (e.g. television). My Hallicrafters SX-42 boat anchor was one of the early receivers that went above the 30MHz; most of its tubes are octals, but it uses miniatures for the upper bands.

Personally I don't like miniatures. I won't deny their advantages, but I don't like some of the small, annoying disadvantages that come with them. First off, they're all glass, which means if you drop them they're more likely to crack or break than a metal-clad octal. The second is that, depending on the manufacturer, the paint can be substandard and easily wiped off. I've got glass octals and pre-octals with markings that are extremely faint, but still legible if you hold them to the light at just the right angle. But I have a lot of minis where the paint is gone without a trace. I've found that you can clean the glass on pre-octals, octals and Loktals with soapy water or glass cleaner without harming the paint, but on some minis the paint disappears. I've accidentally damaged the paint on some by accidentally wiping it with a dry thumb. If you accidentally wipe the designation off the tube, you've likely made it worthless since tubes are very difficult to positively identify by sight alone. It also annoys me that the pins get bent; I'm always worried that I'll break something when straightening them again.

.jpg) There are other tubes, like Compactrons, which resemble miniatures but have more pins, but I believe they should be listed separately. For purposes, miniature tubes are the 7 and 9-pin variety.

There are other tubes, like Compactrons, which resemble miniatures but have more pins, but I believe they should be listed separately. For purposes, miniature tubes are the 7 and 9-pin variety.

Others

There are all sorts of other tubes that use bases that I didn't discuss above. For our purposes (since I'm really limiting this to receiving tubes—the types that are found in most radios and audio equipment), those are the ones you'll come across 99.9% of the time. But there are a few that I'll mention here anyway.

Compactrons were introduced by General Electric in 1961, just as solid-state was solid state was rapidly developing and taking over. They look like large miniature tubes, but they have 12 pins instead of 7 or 9. Compactrons are typically found in televisions or in home-brew ham radios.

Nuvistors came from RCA in 1959. They were, in my non-expert opinion, the next evolutionary step from miniature tubes, but they came too late in the day and lost out to solid-state. They're very small, along the lines of a pencil's eraser end. They were metal clad, not glass. They had even better capacitance specs than miniatures, which made them better for VHF and UHF applications. Expect to find them in RCA televisions, possibly in portable RCA FM radios, from the 1960s.