Please note: this radio is no longer in my collection. I am leaving this here for archival purposes.

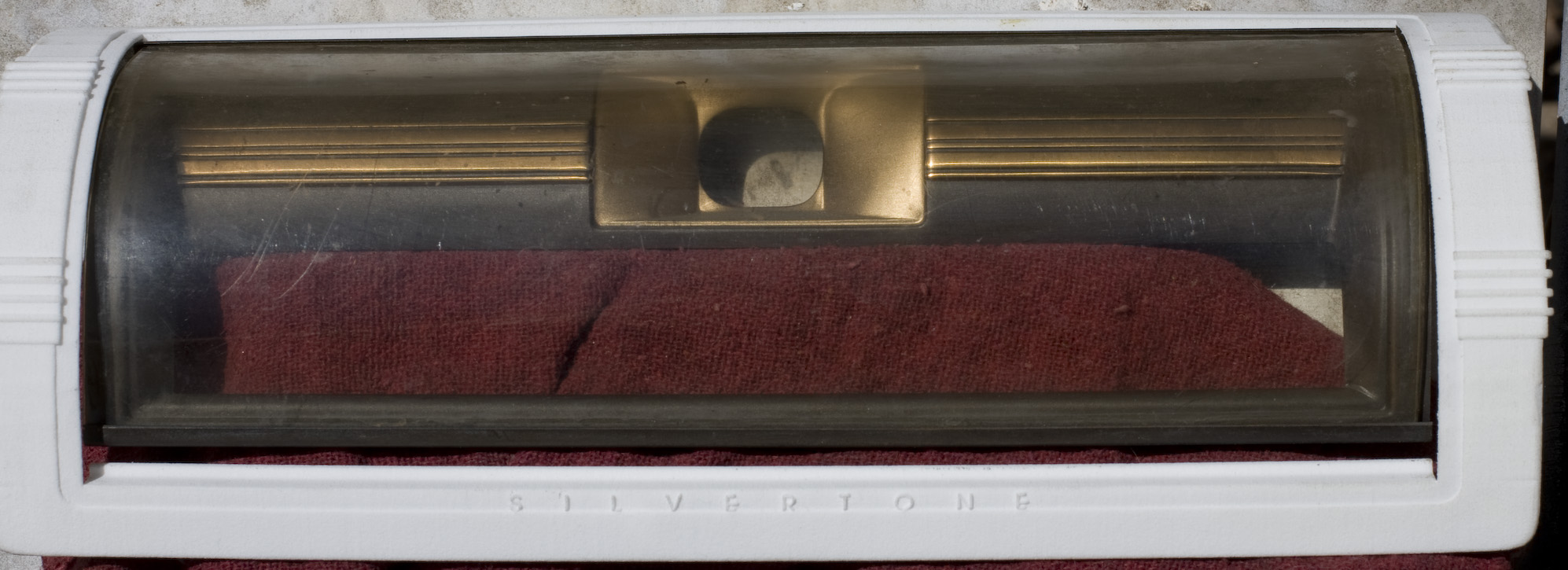

The escutcheon (the trim piece that goes around the clear dial cover on the front of the radio) for my Silvertone console was broken. According to others I've talked to, this is very common. The plastic they used in 1937 (I don't know what type) is prone to shrink and warp over time. Considering it's now 80 years old, as I type this in 2017, it's aging about the same way a human does.

Getting another escutcheon was probably impossible unless I was willing to buy another radio with a good eschutcheon and use the radio as a parts donor. That left another option: 3D printing.

Getting a 3D Scan

Initially I thought I would have to do this myself. I've never 3D printed anything and didn't know much. I did know it was a two-part process: I would have to 3D scan it, and then have that scan printed somehow.

There are a variety of ways to 3D scan something, but the fact that my model was broken and would have to be repaired in the "scan" added another layer of complexity to it.

Then I got a very lucky break. The SQCRA has an article written by Gerry O'Hara about restoring a Silvertone 4766, which is a table-model version of my console. Mr. O'Hara's escutcheon was also broken, and in the article he described how he had a replacement 3D printed (pp 9-10). I sent him an email and asked if he had any more. He did not, but he was kind of enough to send me the 3D scan file that he used. So that took care of the scan. Now all I had to do was have it printed.

Before I talk about that, I'm going to say a little more about 3D scans. The document I received is in IGS format (I'm told it's voiced as "eye-jiss"), which is a CAD (computer aided design) format.

Most 3D printers, either the machines being sold for home use, or the online merchants who will print your projects for you, use a different format called STL, which means "stereo lithography." I was able to convert the IGS file to an STL file format, but because I'm a novice at this, I'm not sure how high the fidelity is between the SLT and the IGS data. This becomes a factor later when I try to get this escutcheon printed.

An aside: please don't ask me for the scan file. I don't have permission to share it. If I do get permission, I'll make it available here.

Getting It Printed

There are several companies that take orders online for 3D printing—you upload your scan and they quote a price. If you accept it, they print it and mail it to you. A couple of companies seem to come out at the top of the lists from several different sources, Shapeways and MakeXYZ.

Before I go further: this isn't an endorsement or knock against any company. I'm just describing what I have been going through to get the piece printed.

I started with MakeXYZ because they accepted my IGS file; Shapeways wanted an STL file (most companies seem to want an STL) and I didn't have one at the time. I created the order with MakeXYZ using their online system.

started with MakeXYZ because they accepted my IGS file; Shapeways wanted an STL file (most companies seem to want an STL) and I didn't have one at the time. I created the order with MakeXYZ using their online system.

I got an email back from a human saying that they might not be able to make it because it's too big. The problem is that the escutcheon is a little over 10-inches wide, but most printers I've seen max out at 8- or 9-inches. The person asked if it would be okay to print it in two pieces so it could be glued together. I figured that would be okay and said yes. I was also warned that it was going to be hard to make. I assume that's because of the arched sides.

I later got an email back saying nobody accepted the job. I take it MakeXYZ probably acts as a front end and a number of printing companies look at the available jobs and choose to do the ones they want to do. Nobody wanted mine.

A little later I got another contact asking if I wanted to try again, and asked if I had an STL file. By this time I'd gotten my IGS file converted, and I'd gotten my print from Shapeways, so I told them that yes, I want to try again and gave them my STL file. I'm current waiting for a reply.

A little later I got another contact asking if I wanted to try again, and asked if I had an STL file. By this time I'd gotten my IGS file converted, and I'd gotten my print from Shapeways, so I told them that yes, I want to try again and gave them my STL file. I'm current waiting for a reply.

When MakeXYZ said they couldn't do my file, I checked around and was eventually able to convert the IGS to an STL file, so I tried using Shapeways. I uploaded the file and went through a questionaire asking me various things, like what kind of material I wanted it printed out of. I went with PLA, which is a standard and well-regarded material commonly used by 3D-printers.

Shapeways's system looked over my file and said it was going to be hard to make. The system (this was done entirely online, not through a human intermediary) said it was structurally weak and asked if it could tweak things a little to make it firm enough for printing. I figured that probably meant making the ribs on the underside thicker, which wouldn't affect me. I said yes. Then I got a message that the drawing needed to be scaled slightly. The ratio they gave me (I don't recall what it was, and didn't write it down) seemed insignificant, so I said yes. I think that's where I went wrong.

The job was about $35.

They accepted the job. Took about a week for them to print it, then a little over another week to get it. I'm in California, it came from the East Coast via canal barge (UPS and USPS).

Got it and it looks good. 3D prints are a little rough and need to be sanded. That's fine. But—it's a bit too big. How much too big I haven't really figured out. The problem is that the clear plastic dial cover needs to fit neatly inside, but it doesn't. The escutcheon looks to me to be about 1/16" or so too wide.

Got it and it looks good. 3D prints are a little rough and need to be sanded. That's fine. But—it's a bit too big. How much too big I haven't really figured out. The problem is that the clear plastic dial cover needs to fit neatly inside, but it doesn't. The escutcheon looks to me to be about 1/16" or so too wide.

So this is where I am at the moment. Either I need to get it printed again but make sure the size is correct, or I need to make some kind of mask that will hold the dial glass in place and fill in the gap. That can be done, but it'll be some work.

I never heard back from MakeXYZ, I assume they don't want to do it. I tried a local print shop but they say it's too big and too complicated for them.

I never did finish this project. The radio was given away when I moved out of state.

3D Scan Files for Your Own Project

Gerry O'Hara and the folks at the SPARC museum were kind enough to make the original file available here for download. If you pass it on, please be sure to give the SPARC Museum credit.

The IGS file is their original. The STL file is a conversion I made via an online website.

Right-click and Save as... on this link to get the IGS file version

Right-click and Save as... on this link to get the STL file version