Adding an Oxygen Sensor Ground

I was complaining about a low-idle problem on JaguarForums and got two possible remedies to try. The harder one involved pullng the fuel rail and checking the injectors. The quicker, easier one involved grounding the Oxygen Sensor.

I was complaining about a low-idle problem on JaguarForums and got two possible remedies to try. The harder one involved pullng the fuel rail and checking the injectors. The quicker, easier one involved grounding the Oxygen Sensor.

The Oxygen (aka O2) sensor looks a lot like a spark plug and is mounted on the Y-pipe between the exhaust manifold and the forward catalytic converter. It has a black wire coming out of it which feeds a voltage back to the computer; the computer adjusts the mixture. You could just as easily call it an exhaust gas thermometer, in my opinion.

Like anything electrical, it needs two connections to make a circuit. The black wire is one side, its own body provides the other, the electrical "ground," because it's physically connected to the exhaust pipe, and that ought to be "chassis ground."

But there's a theory that the exhaust pipe can make a poor electrical connection to the rest of the car, and thus makes a poor ground. Just a couple years later, Jaguar changed to a two-wire O2 sensor, with the second wire going to ground.

Jose on Jaguar Forums has a website called JagUpgrades, where he discusses various changes or upgrades that can be done to the XJ6 (through Series 3), and XJS cars. In some cases he sells the parts to do it. He added a ground strap (a heavy braded wire), one end would go under the Oxygen sensor, the other end would go to a better ground location.

Jose on Jaguar Forums has a website called JagUpgrades, where he discusses various changes or upgrades that can be done to the XJ6 (through Series 3), and XJS cars. In some cases he sells the parts to do it. He added a ground strap (a heavy braded wire), one end would go under the Oxygen sensor, the other end would go to a better ground location.

What good does a better ground do? Supposedly it makes the car idle better. I figured even if it didn't solve my problem, it couldn't hurt, and if it helped the idea even somewhat, I would be ahead.

Ordinarily I would try to make one myself but I've got a bunch of other projects going, so I went the lazy way and ordered his ground strap.

And so begins another project that goes in single, hard steps.

First off was getting the old O2 sensor out. It takes a 7/8" wrench, but you can't use a regular socket, not even a deep socket, because of the wire coming out the top. Because of its location, it's too tight to get a standard end wrench on it. Offset wrenches don't offset enough. I almost bought a stubby and I almost bought a ratchet wrench with a hinge on the head, but I couldn't find one locally and didn't want to wait for the FedEx truck.

It turned out I already had the speciality tool I needed. You can get an O2 wrench; it's a deep socket with the side cut out so the wire can come out. I didn't know it existed at the time, so I had asked my father to cut a window out the side of a 7/8-inch deep socket. Looks just like this one from Harbor Freight except that mine's polished-chrome finish. I had used it to compress the valve springs and the open side let me fish out (or install) the keepers.

It turned out I already had the speciality tool I needed. You can get an O2 wrench; it's a deep socket with the side cut out so the wire can come out. I didn't know it existed at the time, so I had asked my father to cut a window out the side of a 7/8-inch deep socket. Looks just like this one from Harbor Freight except that mine's polished-chrome finish. I had used it to compress the valve springs and the open side let me fish out (or install) the keepers.

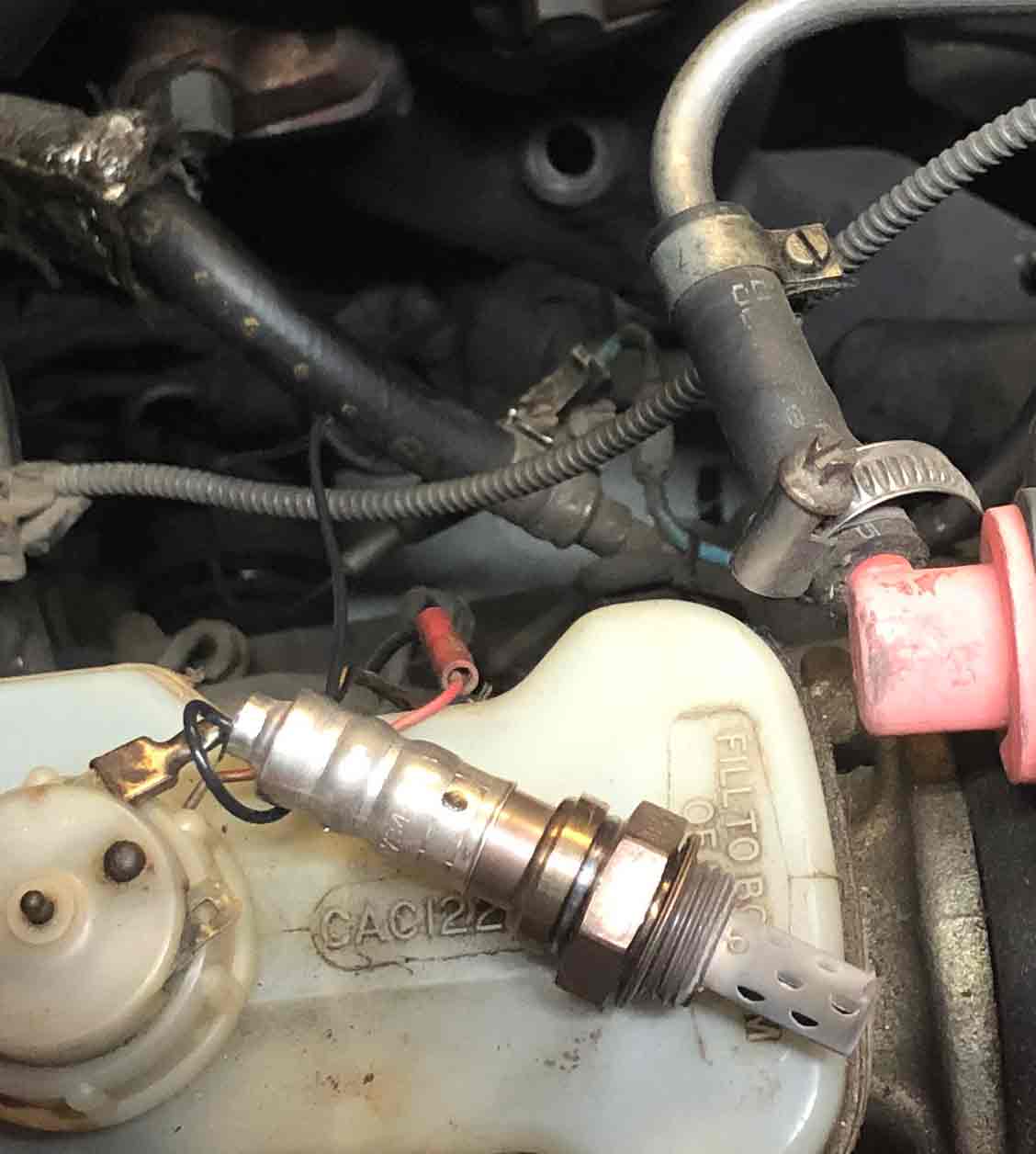

Once I had the socket on the sensor, with an extension and a breaker bar I was able to get the sensor off easily enough. The photo shows it resting on the brake fluid reservoir; you can see the hole where it was installed.

The next problem was getting the old crush-washer off, because like most crush washers, it doesn't want to walk up the threads. I could just get it started but never managed to get it past. Couldn't brute-force it over with a screwdriver. Couldn't twist it with channel-lock pliers, couldn't nip with small wire cutters (broke the cutters) and there's not enough clearance to get the big nippers on it. I finally put a cut-off wheel on the Dremel and cut the damn thing off.

Once that was done, things got far easier. I slipped the new crush washer and the strap collar on, put a dab of high-temp anti-seize compound on the threads, and it went right back in. I couldn't find a torque spec so I just put it in tight. Reconnected the wire and added a glob of dielectric grease under the protective boot.

Figuring out whether to put the other end was a small challenge. I ended up doing what Jose did, which was put it under a bolt that mounts the cruise control bellows to the fender. That required pulling the front tire because my arms were too short and not jointed enough to be able to get to both ends of the bolt at the same time. Once I removed the tire, it was relatively easy.

My experience: it didn't make any difference. Car idles about the same, and I have the same problem. But I didn't hurt anything and as modifications go, it was relatively easy.